The focus on ROI must be forward-looking due to the rapid pace of fundamental changes in today’s industry.

Due to the combination of increased labor rates and more efficient automation equipment and processes, the return on an automation has shortened to about half of what it used to be. As you are evaluating automation solutions, here are three key trends that you should be considering implementing now in order to keep up with the competition.

Robotic Process Automation (RPA)

Go to virtually any trade show for manufacturing and automation and robots and cobots are everywhere.. The advancements and number of providers of RPA is growing and their offerings are becoming more advanced. Reliance on one manufacturer of robots or collaborative robots is not always the best approach and your focus should be on the fit and function of the robotic solution as a tool rather than brand familiarity. Cost, fit and function should be the major deciding factors. Our AUBO line of collaborative robots offers a wide range of products from palletizing to one-of-a-kind welding solutions and product handling to help offset the continuing shortage of a qualified workforce. Aubo

Intelligent Process Automation (IPA)

IPA is a fundamental shift for the future of automation. With current communication capabilities, machines are longer isolated from one another and no longer require physical human interaction for status updates and maintenance assessments as they did years ago. The impact of the trend will exponentially increase in the years ahead particularly with the ability using this communication network to leverage of the continued advancements in Artificial Intelligence. IPA combines RPA with other technologies such as natural language processing, machine learning, and cognitive automation to allow production data and machine health to be available in real time. If you have an interest in or a need for the right communication hardware to improve your IPA capabilities, please consider our CIMON line of PLC’s, IPC’s and HMI Hybrids. CIMON

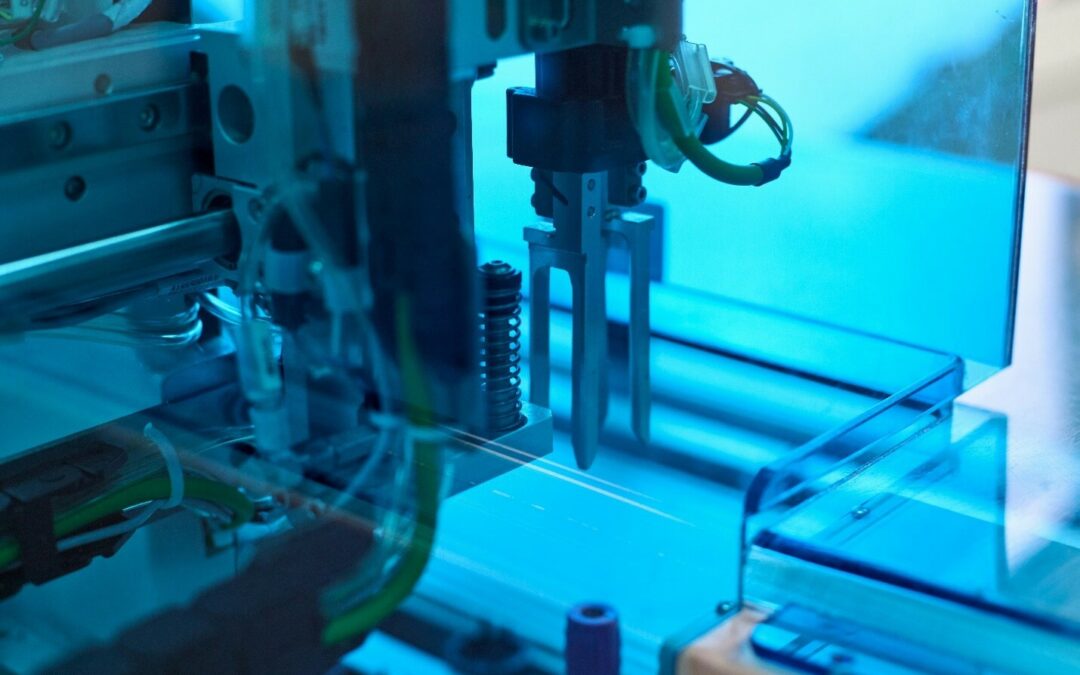

Electrical Motion Automation (EMA)

As automation continues to move forward with more intelligent systems with data being acquired and presented in useful real-time analytics, the need for smarter and more precise subcomponents is very apparent. Legacy motion devices are at best only providing two states of condition or position. With electrically operated linear, multi-axis and actuator components with a much larger range of drive, guide, and profile options of over a million possible configurations, these new systems are providing solutions that offer complete flexibility and traceability. By design they improve productivity, and reliability of equipment, while generating significant energy and efficiency savings thus lowering the total cost of ownership. Their ability to provide information through the combination with other IPA devices and controls in these new systems allows for the customization of pertinent data being immediately available anywhere. EFP has a number of EMA solutions that can take you the next level on your automation journey. Electrical Actuation

Summary

These three automation trends will have a significant impact across various industries paving the way for increased productivity, improved customer experiences, and innovative business models. Is it time to consider the various RPA, IPA and EMA components to replace some of your legacy automation and human processes?If so, there are many viableoptions available that can deliver the return and improve your processes.

Let EFP Industrial Automation show you how to move forward in 2024!