Pneumatic Valves

Features and Benefits of Pneumatic Valves

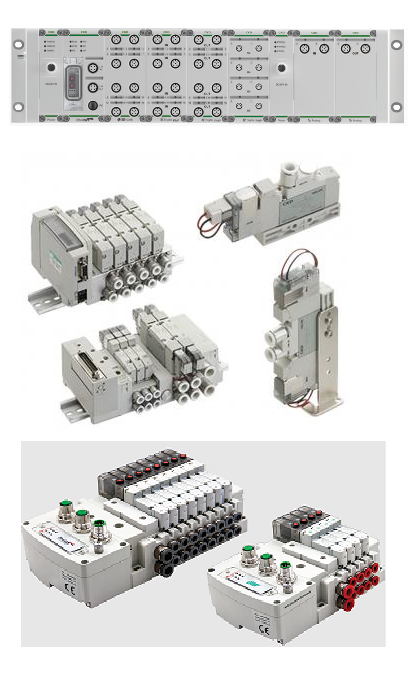

Types of Pneumatic Valves

Air Pilot | Manual | Mechanical

Manual or mechanical valves are often used in more traditional installations. Manual valves are directly actioned by the operator. Mechanical valves are where the machine or process will operate or trip the valve. Air pilot valves help simplify pneumatic circuits by eliminating electrical wiring. Available in multiple port sizes, these valves can be piped individually or used with manifolds to reduce plumbing. Two- and three-position models are available to fit your application and feature dual exhaust ports.

Discrete | Fieldbus | I/O

Pilot-Operated | Check | Logic

Why Choose Our Pneumatic Valves

The EFP Edge

EFP proudly demonstrates excellence with our pneumatic valves product collection. These valves play a vital role in ensuring the flawless operation of your machinery. Recognizing the dual need of staying within budget and meeting deadlines, whether it be a brand new machine delivery or managing downtime due to a part issue, EFP emerges as the most trustworthy partner to count on for timely delivery and accurate quotes.

Our commitment to your success is unparalleled. That’s why we’ve introduced our exclusive Rapid Response Guarantee. We vow to address your online chats within 60 seconds and to handle web inquiries within 60 minutes during our business hours. If we miss the mark, we’ll discount $60 from your next purchase. Our unwavering dedication to superior customer service has been our hallmark since 1975.

Operating from Ohio and extending our services to customers in Kentucky and Indiana, EFP promises a personalized touch with the support of our seasoned team. They stand ready to ensure all your demands, preferences, timelines, and budgetary needs are met consistently. Equipped with unmatched speed, deep expertise, firm accountability, and utmost integrity, our enduring partnership with your company guarantees your success.

Together, we deliver.